Packaging Machine Builder?

Cut Warranty Cost by 60%.

Instantly improve machine performance and reduce warranty cost with the #1 packaging machine performance service in the world.

OEMs and End Users

Who Depend on Wave7

How Does Wave7 Work?

Wave7 lets you improve packaging machine and line performance in real time. Here's how it works...

Step 1: Listen

You’ll never wonder if your machine is treating your customer right (or vice versa!). Active Alerts sends you a text or email letting you know a machine is down or is heading there.

Step 2: Understand

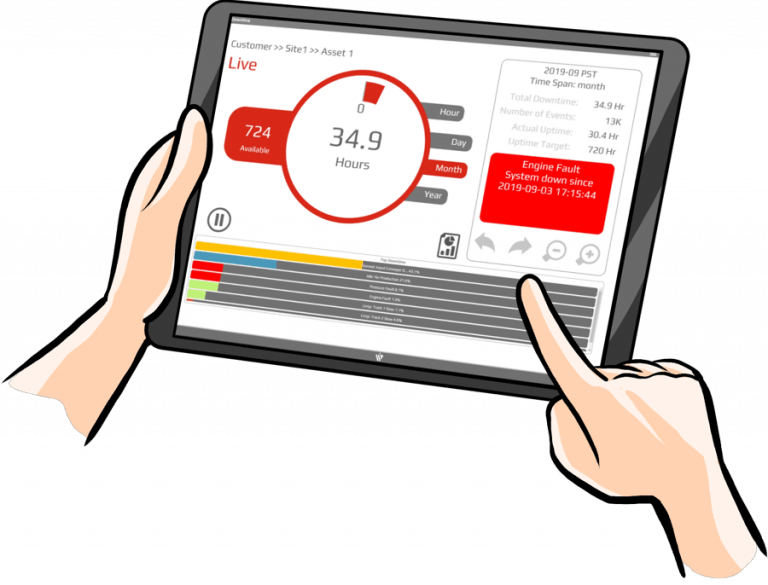

So now you know you’ve got trouble, and Wave7 can help you pinpoint it in less than 60 seconds. Use the Downtime App or Production App to identify the issue and troubleshoot the cause – in real time.

Step 3: Take Action

No one wants the angry call from the customer, so fix it! Log in with Remoter VPN, troubleshoot the issue and contact your customer if needed.

No Programming, Just Amazing Results

Wave7 isn't a toolkit, it's a fully developed IoT to Cloud service.

All you have to do is use it.

Wave7 Benefits for Machine Builders

Up to 50% increase in capacity

Every loss time event is money out the door and aggravation for your customer, regardless of the cause.

Your expertise in combination with Wave7 will pinpoint issues in real-time and help keep that machine running with up to 50% more uptime.

Up to 60% warranty cost reduction

Never travel onsite for diagnostics again. Wave7 will Alert you via text or email, show you the cause and provide remote access to your machine.

If there is a problem that requires an onsite visit, go knowing the issue and shorten the trip and costs dramatically.

Up to 90% reduction in troubleshooting time

What’s the most challenging part of a trouble call from your customer? The customer.

With Wave7, you’ll know exactly what the problem is before you talk to the customer. In most cases, you’ll know about the problem *before* your customer does.

Know about problems before your customer

Wave7’s Active Alerts allows you to build a suite of alerts that will text or email when your machine is heading towards trouble.

Wave7 helps diagnose the issue, letting you schedule a fix when your customer has a planned stoppage – not during production!

Automatically find problems that are similar across your entire fleet

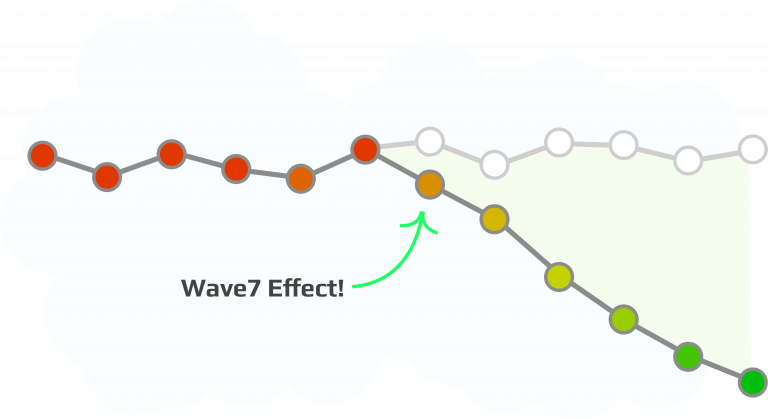

Wave7 keeps an eye out for systemic issues across similar machines, and provides analytics and data that let you find and understand areas for improvement.

Imagine if you knew the same part was failing on 50% of your machines at 500 hours!

Create a deeper partnership with your customer

Imagine if the new sports car you bought came with a pit crew and engineering team?

While everyone else is just selling a machine, you’ll be partnering in their packaging success.

Gain new revenue

Your customers are begging for high performance packaging, and you ARE the experts.

Not only can you provide Wave7 apps, you can also create value add performance monitoring, guaranteed Service Level Agreements, and even Machine as a Service offerings.

Be Different. Be Better.

The market has been waiting for Machine Builders who partner with their customers for performance.

So jump ahead of your competition, and provide true value to your customer by using Wave7 for packaging performance improvement.

The Wave7 Story

I’m David McKay, the President and founder of Wave7, the #1 performance improvement service for packaging lines.

Wave7 is used around the world to improve machine and human performance on packaging machines and packaging lines. Why? Because Wave7 has three unique advantages:

Wave7 is both a performance improvement method (M2L) and app

Wave7 is a service, not a toolkit you have to provision and build

Wave7 only presents actionable information

Stop wondering how to get data, and start using Wave7

For the past 25 years I’ve either been using, developing or delivering software and hardware that delivers information from manufacturing, IT or machines to humans. The express goal was always to improve performance, but something was always missing. Several somethings, actually.

When you get raw data from any kind of process, you have turn it into actionable information. Actionable information requires:

Correlation. The data needs to be assigned to some real world events.

Aggregation. The correlated data needs to be put into containers that can be assigned to assets and a date/time event (like a shift).

Analytics. The aggregated data must be turned into actionable information.

Methodology. Actionable information needs to be modified to fit within a method for improvement that people understand.

Presentation. Actionable information must be real-time, with push alerts and interactive apps, available on any device.

Guess what? That’s a big ask.

It's all about the method

If you want to build a winning race car, you don’t throw a bunch of random speed parts at it and hope. You need a method to improve man and machine at every race. If you stick to the method and keep adapting to changing conditions, over time you WILL improve.

That’s the basis for Wave7’s success. We’ve developed the best in class performance improvement method for packaging machines and packaging lines, and we’ve baked into our cloud service.

Don't analyze, take action!

Everything in Wave7 is actionable. Our goal is for you to do one of two things:

Look at the Wave7 app and move directly to the problem location, OR

Click on the Wave7 metric, drill down to the specific issue, THEN move directly to the problem location

I don’t want you to schedule a meeting or open an excel spreadsheet, I want you to be able to get a notification, look at Wave7 and move to the problem.

Don't try to build it, just use it

The usual suspects, Rockwell, Siemens, Schneider, Wonderware (Aviva), et all., would have you believe you should build it yourself. BS!

You aren’t a software company. Nor are you a performance consultant, or security expert or any of the other things it takes to run software as a service. We’ve spent more than 50 man years building out a solution so you can just use it.

Stay with your expertise in manufacturing the best products in your industry, and we’ll help you put them in boxes better and faster than you ever have before.

Feel free to reach out to us at any time.

Cheers,

David McKay