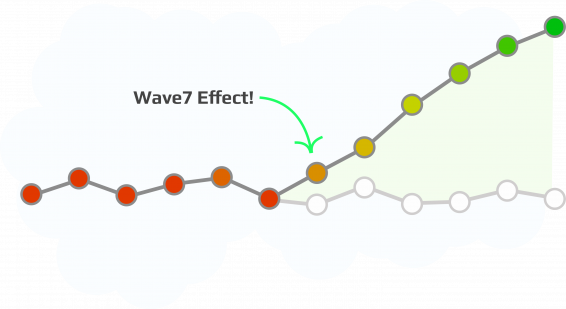

Increase packaging line performance by 50%.

Instantly increase packaging line performance with the #1 packaging performance improvement service in the world.

Customers

Who Depend on Wave7

How Does Wave7 Work?

Wave7 helps you increase packaging line performance in real time. Here's how it works...

Step 1: Wave7 is ready to go

Getting going with Wave7 couldn’t be easier. Our WaveRider data collector gets installed on your line and within 3-4 hours the WaveRider is pushing raw data to our cloud based packaging line performance analytics. Within seconds, the raw data is converted to actionable info and pushed directly to you. No more building excel reports and conducting end of week meetings, you are improving performance RIGHT NOW.

Best of all? No servers, no software, no programming, just results.

Step 2: Use our method and tool

Wave7 succeeds where others fail, because Wave7 isn’t just a visual tool.

Wave7 has the Best-In-Class performance improvement method – M2L – baked directly into the DNA of our service.

This means you get a culture changing, industry independent, massively successful machine and human performance service that is proven across industries.

Step 3: Change your culture overnight

Wave7 does three things that are an absolute must for massive packaging performance improvement:

Wave7 puts our culture changing Predictive Performance Kiosk on big screen TVs located above or beside your packaging line, enabling you influence behavior immediately

Wave7 delivers immediate and interactive drill downs on any problem from any smartphone, tablet or PC

Wave7 pushes actionable ALERTS to every device type through text and email, prompting immediate action

Step 4: Use our experience

Wave7 is a subscription service, which means we are invested in your success. You get to leverage our expertise and knowledge, and it happens fast:

We install within 2 weeks of your order date, you start getting actionable information day 1

During the first 1-3 weeks of run time we help you vet the information with your team

We provide additional on and offsite coaching services to help you navigate culture change and be successful; you are never alone with Wave7

Step 5: Enjoy your success

Wave7 powered packaging lines see improvement within the first month, and return on investment is almost always within 2-6 months.

So why not enjoy up to 50% increase in capacity, 90% decrease in troubleshooting time, and happier teams?

Wave7 is here to help you blow the doors off your packaging performance, all you have to do is use it.

No Programming, Just Amazing Results

Wave7 isn't a toolkit, it's a fully developed IIoT to Cloud service.

All you have to do is use it.

Wave7 Benefits for Packaging Lines

Increase packaging line performance by 50%

Every loss time event is money out the door and contributes to missed deliveries and unhappy customers.

Wave7 will pinpoint issues in real-time, direct you to the source and help keep that packaging line running with up to 50% more uptime.

Blow up your culture!

Stop trying to get buy-in the old way. Empower your plant floor staff with our groundbreaking Predictive Performance Kiosks. They change cultures with ACTIONABLE, easy, and gamified performance displays.

No abstract metrics, just simple, visual and relatable kiosks that prompt action and healthy competition.

Best in Class Performance Methodology

Are you trying to invent your own performance improvement system?

Wave7 has taken our best in class method (M2L) and combined it with the best in class cloud service. Installation is less than a day, and then you just use it!

Know about problems before they occur

Wave7’s Active Alerts allows you to build a suite of alerts that will text or email when your machine is heading towards trouble.

Wave7 helps diagnose the issue, letting you schedule a fix during a planned stoppage – not during production!

Automatically find similar problems across the enterprise

Wave7 keeps an eye out for systemic issues across similar machines and lines, and provides analytics and data that let you find and understand areas for improvement.

Take advantage of our performance experience

Imagine if the new sports car you bought came with a pit crew and engineering team?

Wave7 provides expert performance and culture services, helping you perform better!

Cut packaging costs by 30%

Cut rework, lost product, lost packaging material, and wasted labor. Hit your shipping deadlines without penalties, and keep those customers happy.

Partner with your machine builders.

Your machine builders are the experts, and hate getting unhappy calls. Provide them with a user license for Wave7, and engage them in your road to success.

The Wave7 Story

I’m David McKay, the President and founder of Wave7, the #1 performance improvement service for packaging lines.

Wave7 is used around the world to improve machine and human performance on packaging machines and packaging lines. Why? Because Wave7 has three unique advantages:

Wave7 is both a performance improvement method (M2L) and app

Wave7 is a service, not a toolkit you have to provision and build

Wave7 only presents actionable information

What is a packaging performance service?

For the past 25 years I’ve either been using, developing or delivering software and hardware that delivers information from manufacturing, IT or machines to humans. The express goal was always to improve performance, but something was always missing. Several somethings, actually.

When you get raw data from any kind of process, you have turn it into actionable information. Actionable information requires:

Correlation. The data needs to be assigned to some real world events.

Aggregation. The correlated data needs to be put into containers that can be assigned to assets and a date/time event (like a shift).

Analytics. The aggregated data must be turned into actionable information.

Methodology. Actionable information needs to be modified to fit within a method for improvement that people understand.

Presentation. Actionable information must be real-time, with push alerts and interactive apps, available on any device.

Guess what? That’s a big ask.

It's all about the method

If you want to build a winning race car, you don’t throw a bunch of random speed parts at it and hope. You need a method to improve man and machine at every race. If you stick to the method and keep adapting to changing conditions, over time you WILL improve.

That’s the basis for Wave7’s success. We’ve developed the best in class performance improvement method for packaging machines and packaging lines, and we’ve baked into our cloud service.

Don't analyze, take action!

Everything in Wave7 is actionable. Our goal is for you to do one of two things:

Look at the Wave7 app and move directly to the problem location, OR

Click on the Wave7 metric, drill down to the specific issue, THEN move directly to the problem location

I don’t want you to schedule a meeting or open an excel spreadsheet, I want you to be able to get a notification, look at Wave7 and move to the problem.

Don't try to build it, just use it

The usual suspects, Rockwell, Siemens, Schneider, Wonderware (Aviva), et all., would have you believe you should build it yourself. BS!

You aren’t a software company. Nor are you a performance consultant, or security expert or any of the other things it takes to run software as a service. We’ve spent more than 50 man years building out a solution so you can just use it.

Stay with your expertise in manufacturing the best products in your industry, and we’ll help you put them in boxes better and faster than you ever have before.

Feel free to reach out to us at any time.

Cheers,

David McKay